البطريق طائر من ناحية رسم البطريق البطريق التوضيح البطريق التوضيح, البطريق, ريشة سوداء, الريشة البيضاء PNG وملف PSD للتحميل مجانا | Superhero, Character, Animals

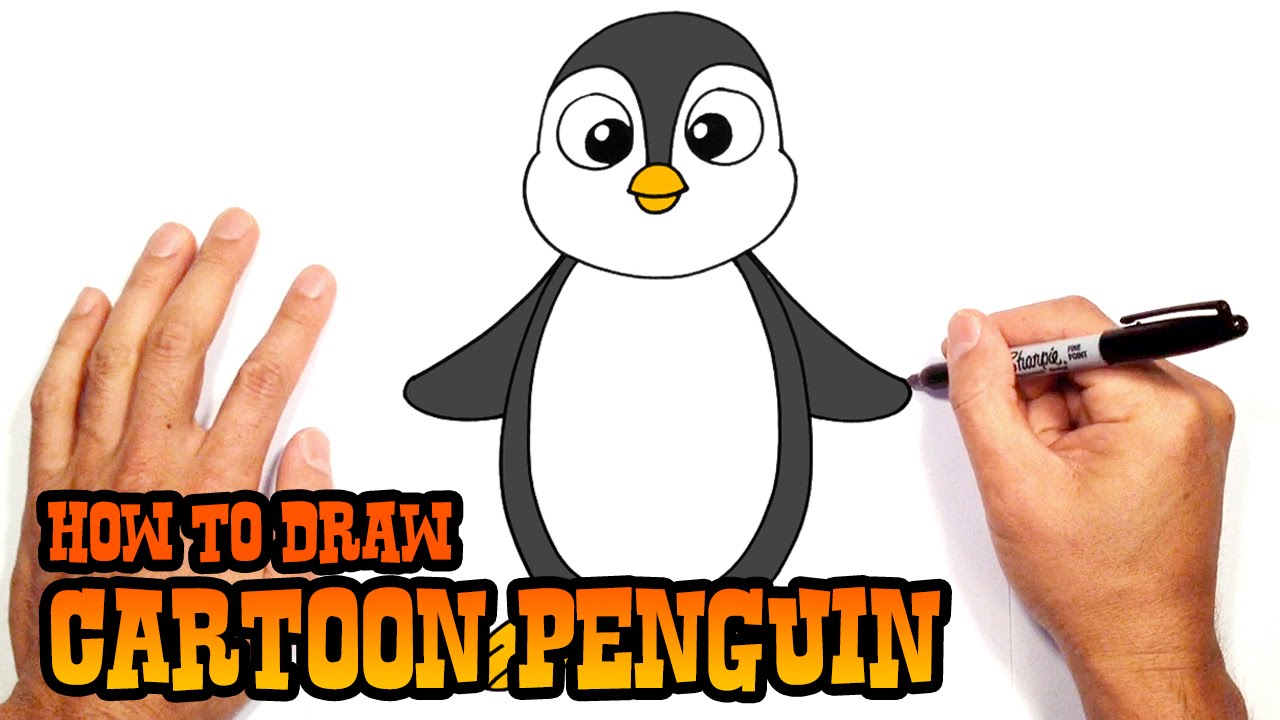

كيف ترسم بطريق سهل خطوه بخطوه للمبتدئين/رسم بطريق/رسم سهل/تعليم الرسم خطوه بخطوه للمبتدئين - YouTube

البطريق ، الرسم ، البطريق الإمبراطور ، التكس ، البطريق الملك ، الطيور ، الطيور التي لا تحلق ، منقار, منقار, طائر, رسم png

تعليم رسم بطريق سهل بالخطوات | رسم سهل جدا | رسومات سهلة للمبتدئين | How to draw a penguin - YouTube

الكرتون ناقلات من ناحية رسم البطريق لطيف, البطريق المرسومة, ناقلات الكرتون, ناقلات اليد PNG وملف PSD للتحميل مجانا